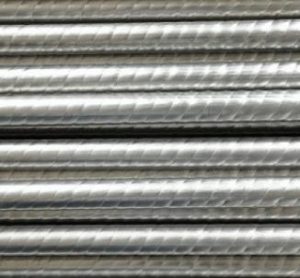

The threaded tube, which is the core heat transfer element of a heat exchanger, is also called a low-ribbed tube. The heat exchanger tube improves heat transfer performance, controls volume and mass, and saves material, which is important for improving heat exchanger efficiency and reducing costs. High efficiency heat exchanger tube technology commonly uses threaded tubes. Compared with the traditional smooth tube, it has the advantages of high heat transfer efficiency, less fouling, small volume and material saving.

Spiral steel pipe or spiral welded pipe is also some names for spiral pipe. It is made by rolling a strip of low carbon structural steel or low alloy structural steel into a pipe billet according to a certain spiral angle (called forming angle) and then welding the pipe seam. Large diameter steel pipes with narrower strips can be produced. Spiral pipe is mainly used for oil and gas pipelines, single-sided welded and double-sided welded is the welding method of spiral pipe. It should ensure that the welded pipe meets the requirements of hydraulic test, weld tensile strength and cold bending performance.

The following mainly introduces to you what is the difference between threaded pipe and spiral pipe?

1. Performance characteristics are different

The performance of spiral pipe has good bending strength, the product has a long service life, beautiful appearance, acid and alkali resistance, corrosion resistance. Stainless steel threaded pipe is an environmentally friendly product that can replace traditional carbon steel, aluminum and copper products. Due to the surface tension of the threaded steel pipe, it also has a very good strengthening effect on the condensation and boiling outside the pipe. The combination of threaded tube and baffle not only reduces the vibration problem of the heat exchanger, but the coefficient of the cross-flow heat exchanger is about 30% higher than that of the bowed baffle.

2. Different process

Spiral steel pipe is completely called spiral welded steel pipe, which is a kind of spiral steel pipe made of strip steel coil with automatic double-wire submerged arc welding process, usually using hot extrusion forming and double-wire double-sided automatic submerged arc welding process, surface spiral welding, called spiral welded pipe.

Rebar pipe is the outer surface of the steel pipe that is embossed with embossing equipment. Threaded pipe is also known as low-ribbed pipe, mainly relying on the external finned tube to expand the heat transfer area, usually in the tube heat transfer coefficient is greater than double the use of higher than the outside of the pipe.

3.Different application occasions

Oil drilling, geological drilling, shipbuilding, machinery manufacturing, aircraft and vehicle manufacturing, as well as the defense industry and daily light industry are the main areas in which spiral steel pipe is used.

The spiral steel pipe is widely used in chemical industry, construction, boiler manufacturing and low pressure steam pipe for heat exchange and refrigeration equipment.

The two products of stainless steel threaded pipe and spiral pipe are not quite the same. Therefore, in the future use process, to distinguish them clearly. Only in this way can we make better use of the performance of threaded and spiral pipes, so that they can better go to our use!

The two products of stainless steel threaded pipe and spiral pipe are not quite the same. Therefore, in the future use process, to distinguish them clearly. Only in this way can we make better use of the performance of threaded and spiral pipes, so that they can better go to our use!