Steel pipes are essential components in the construction and infrastructure industries, used for everything from transporting water and gas to creating bridges and buildings. But how are these pipes made? This article will provide an overview of the manufacturing process for steel pipes, from the initial production of steel to the final product. We will explore the different types of steel pipes and their applications, as well as the benefits of using steel pipes in construction and infrastructure projects.

Quotation

Steel pipes are critical components in various industries, including construction and infrastructure. But how are these pipes made? This article will provide an overview of the manufacturing process for steel pipes, from the initial production of steel to the final product. We will also discuss the different types of steel pipes and their applications, as well as the benefits of using steel pipes in construction and infrastructure projects.

The Manufacturing Process for Steel Pipes

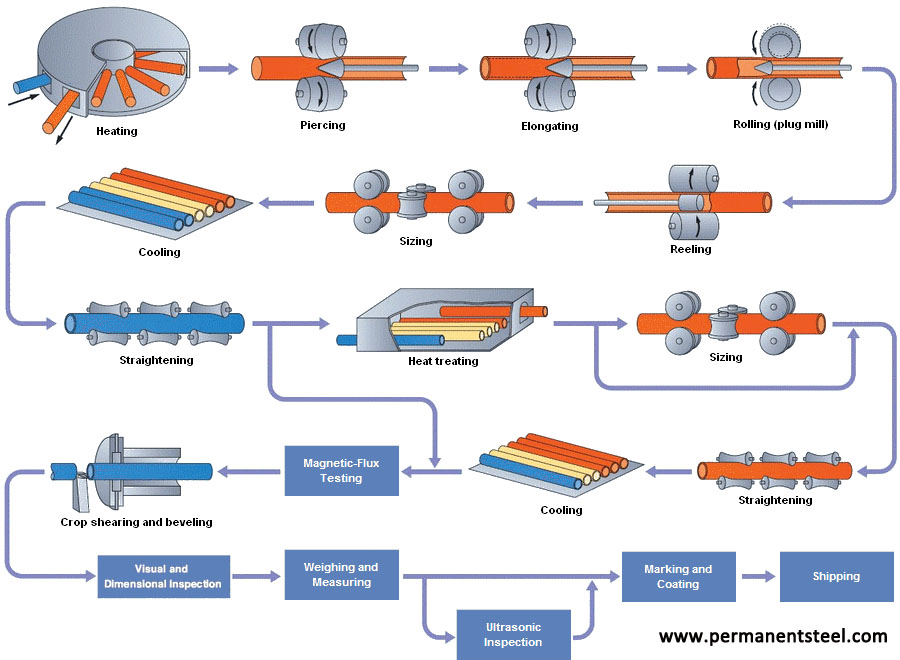

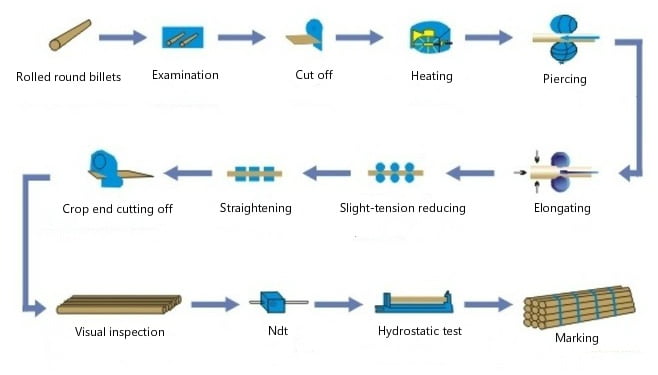

The manufacturing process for steel pipes involves several steps, including the production of steel, the creation of pipe blanks, and the formation of the final product. Steel is first produced in a blast furnace or electric arc furnace, and then shaped into pipe blanks through a process called rolling. The pipe blanks are then shaped into the final product through various methods, including seamless and welded pipe manufacturing.

Types of Steel Pipes and Their Applications

There are various types of steel pipes used in different applications, including carbon steel pipes, stainless steel pipes, and galvanized steel pipes. Carbon steel pipes are the most commonly used type and are used in applications such as transporting gas and oil. Stainless steel pipes are used in applications where corrosion resistance is required, such as in food processing or medical equipment. Galvanized steel pipes are used in applications where rust prevention is required, such as in outdoor structures or water systems.

Benefits of Using Steel Pipes in Construction and Infrastructure

Steel pipes offer numerous benefits in construction and infrastructure projects, including their strength, durability, and resistance to corrosion. They are also cost-effective, as they require less maintenance and have a longer lifespan than other materials. Steel pipes are also recyclable, making them a sustainable option for various applications.

Conclusion

Steel pipes are critical components in the construction and infrastructure industries, used for everything from transporting water and gas to creating bridges and buildings. The manufacturing process for steel pipes involves several steps, including the production of steel and the formation of the final product. By understanding the different types of steel pipes and their applications, as well as the benefits of using steel pipes in construction and infrastructure projects, builders and developers can make informed decisions and create structures that will stand the test of time.