Glued Hooked End Steel Fiber is a popular additive used in concrete to enhance its mechanical properties. This article discusses the benefits of using this fiber in concrete, including improved tensile and flexural strength, increased durability and resistance to cracking, and enhanced toughness. Additionally, it explores the various types of steel fibers available, their manufacturing process, and how to effectively use them in concrete mixtures.

Introduction:

Concrete is a widely used construction material due to its strength, durability, and affordability. However, it has its limitations, particularly when it comes to tensile and flexural strength. To address this issue, engineers have turned to reinforcing concrete, which involves adding steel bars or mesh to the concrete mixture. While this technique has proven effective, it can be time-consuming and labor-intensive. Fortunately, there is an alternative solution: glued hooked end steel fiber.

What is Glued Hooked End Steel Fiber?

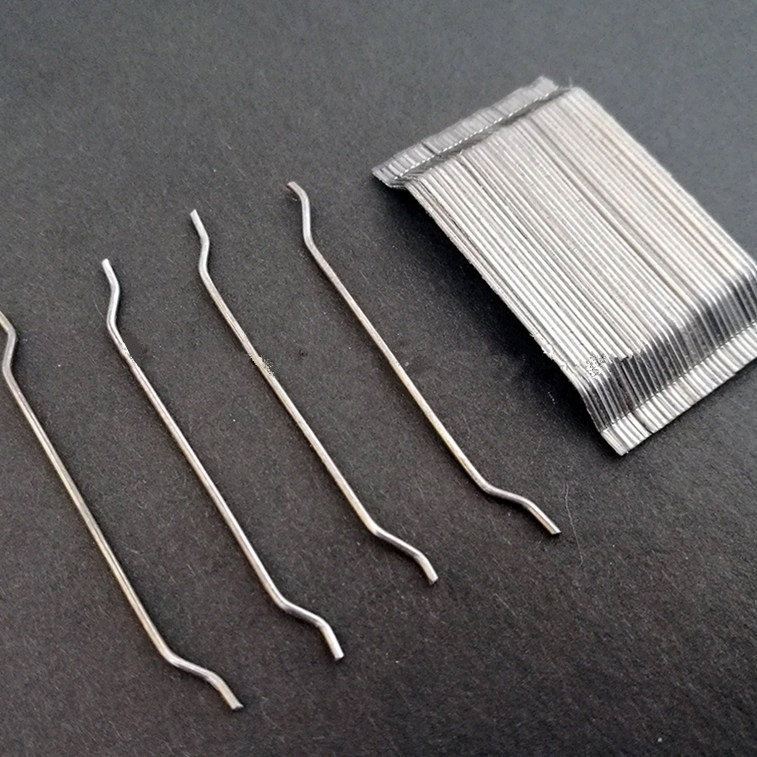

Glued Hooked End Steel Fiber is a type of reinforcement material that is added to concrete mixtures to improve their mechanical properties. This fiber is manufactured by gluing small pieces of steel wire together to form a bundle, which is then cut and hooked at the ends to create a specific shape. The hooked ends of the fiber helps to anchor it in the concrete matrix, improving its bond strength and overall performance.

Benefits of Using Glued Hooked End Steel Fiber in Concrete:

- Improved Tensile and Flexural Strength: Glued Hooked End Steel Fiber helps to improve the tensile and flexural strength of concrete by distributing the load more evenly throughout the mixture. As a result, it reduces the likelihood of cracking and improves the overall durability of the structure.

- Increased Durability and Resistance to Cracking: Concrete structures are subject to a variety of stresses, including temperature changes, moisture, and chemical exposure. Glued Hooked End Steel Fiber helps to reduce the impact of these stresses by improving the overall toughness and durability of the concrete.

- Enhanced Toughness: Glued Hooked End Steel Fiber helps to enhance the toughness of concrete by absorbing and redistributing energy during impact. This makes it particularly useful in applications where impact resistance is a concern, such as in airport runways, industrial floors, and parking garages.

Types of Steel Fibers:

There are several types of steel fibers available, each with its own unique properties and characteristics. These include:

- Hooked End Steel Fiber: This is the most common type of steel fiber used in concrete. It is available in a variety of lengths and diameters and is known for its excellent bond strength and durability.

- Straight Steel Fiber: Straight steel fibers are typically used in applications where high strength is required. They are available in a range of lengths and diameters and are often used in precast concrete elements.

- Crimped Steel Fiber: Crimped steel fibers are designed to improve the bond strength between the fiber and the concrete matrix. They are available in a range of shapes and sizes and are often used in shotcrete applications.

How to Use Glued Hooked End Steel Fiber in Concrete:

To effectively use glued hooked end steel fiber in concrete, it is important to follow a few key guidelines:

- Determine the appropriate fiber dosage based on the type of application and the desired performance characteristics.

- Add the fiber to the concrete mixture during the mixing process, ensuring that it is evenly distributed throughout the mixture.

- Use a high-quality concrete mix with the appropriate water-cement ratio to ensure that the mixture is workable and easy to place.

Conclusion:

Glued Hooked End Steel Fiber is a versatile and effective additive that can significantly improve the mechanical properties of concrete. By enhancing its tensile and flexural strength, increasing its durability and resistance to cracking, and improving its toughness, this fiber can help to create more resilient and long-lasting concrete structures. When used correctly, glued hooked end steel fiber can be a cost-effective and efficient alternative to traditional reinforcement techniques.