Dive into the world of welded pipe types in this detailed guide. We’ll cover the most common types, their applications, and the advantages they offer. Whether you’re in the construction industry or simply curious about pipes, this article provides valuable insights into the world of welded pipes.

Introduction to Welded Pipe Types

Welded pipes are vital components in many industries, offering strength and reliability. This section provides an overview of the different types of welded pipes and the processes used to create them.

Common Types of Welded Pipes

There are several common types of welded pipes, including:

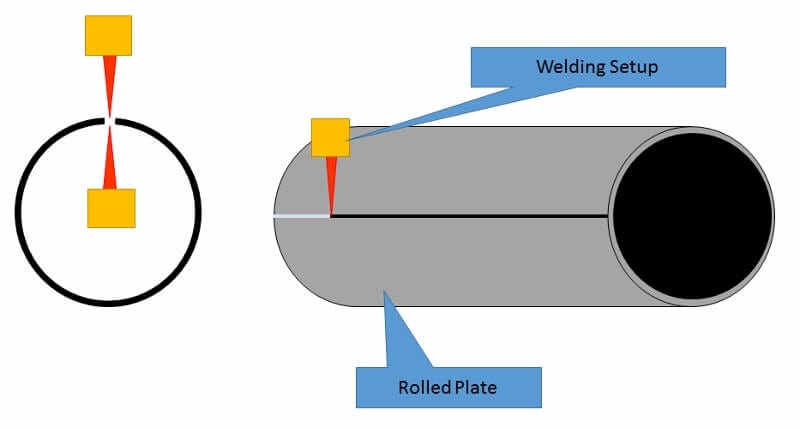

- ERW (Electric Resistance Welded) Pipes: These pipes are made by rolling a sheet of steel into a tube and welding the edges together using electrical resistance.

- LSAW (Longitudinal Submerged Arc Welding) Pipes: LSAW pipes are known for their large diameter and are often used in the construction of oil and gas pipelines.

- SSAW (Spiral Submerged Arc Welding) Pipes: SSAW pipes are created by spiral welding a steel coil, making them suitable for high-pressure applications.

- DSAW (Double Submerged Arc Welding) Pipes: DSAW pipes are formed by welding two submerged arcs simultaneously, ensuring a strong and reliable seam.

Applications of Welded Pipe Types

Welded pipes find applications across various industries, such as:

- Oil and Gas: LSAW and SSAW pipes are commonly used for transporting oil and gas over long distances.

- Construction: ERW pipes are favored for building structures, while DSAW pipes are used in constructing bridges and tunnels.

- Water Supply: Welded pipes are essential for delivering clean water to homes and industries.

- Automotive: These pipes are used in the production of automobile frames and exhaust systems.

Advantages of Welded Pipes

Welded pipes offer several advantages, including:

- Strength: The welded seam provides structural integrity and durability.

- Cost-Efficiency: Welded pipes are often more cost-effective than seamless pipes.

- Customization: They can be produced in various sizes and lengths to meet specific project requirements.

- Environmental Benefits: Welded pipes produce less waste during production, making them more environmentally friendly.

Choosing the Right Welded Pipe

Selecting the appropriate welded pipe type for your project is crucial. Consider factors like the intended application, required diameter, and environmental conditions. Consulting with a professional can help you make an informed decision.

Conclusion

In conclusion, understanding the different types of welded pipes and their applications is essential for professionals in various industries. Welded pipes offer strength, reliability, and cost-efficiency, making them a preferred choice for many projects.